You walk into your garage one morning and notice thin lines running across your concrete floor. Or maybe you spot a hairline crack zigzagging through your concrete driveway after a particularly hot summer, followed by freezing temperatures. Don’t panic, you’re not alone. Temperature changes cause concrete surfaces to expand and contract, leading to these common issues that many homeowners face.

The quick answer: Most hairline cracks in concrete can be successfully repaired using concrete crack filler, concrete sealer, or epoxy injection methods. While many small cracks are purely cosmetic, addressing them promptly prevents further damage and keeps your concrete surface looking its best. The basic process involves cleaning the crack thoroughly, applying the right filler material, and sealing the area to protect against future issues.

Whether you’re dealing with cracks in your garage floor, concrete driveway, or any other concrete surface, this guide will walk you through everything you need to know. We’ll cover how to identify different types of cracks, what materials work best, and when it’s time to call in the professionals.

Understanding What Causes Hairline Cracks in Concrete

Concrete naturally develops cracks as it ages, and understanding why helps you choose the right repair approach. As concrete cures, it shrinks slightly, which can create hairline cracks even in perfectly installed surfaces. This is completely normal and doesn’t indicate poor workmanship.

Common Causes of Concrete Cracking

Temperature changes are the biggest culprit behind crack formation. During hot weather, concrete expands, and when temperatures drop, it contracts. This constant movement puts stress on concrete structures, eventually leading to thin cracks that appear seemingly overnight. Weather conditions also play a major role; areas with dramatic seasonal temperature swings see more cracking than regions with stable climates.

Heavy loads can also contribute to crack development. Your concrete driveway might handle daily car traffic just fine, but parking a loaded moving truck or construction equipment can create stress that leads to new cracks or makes existing ones worse.

Identifying Different Types of Cracks

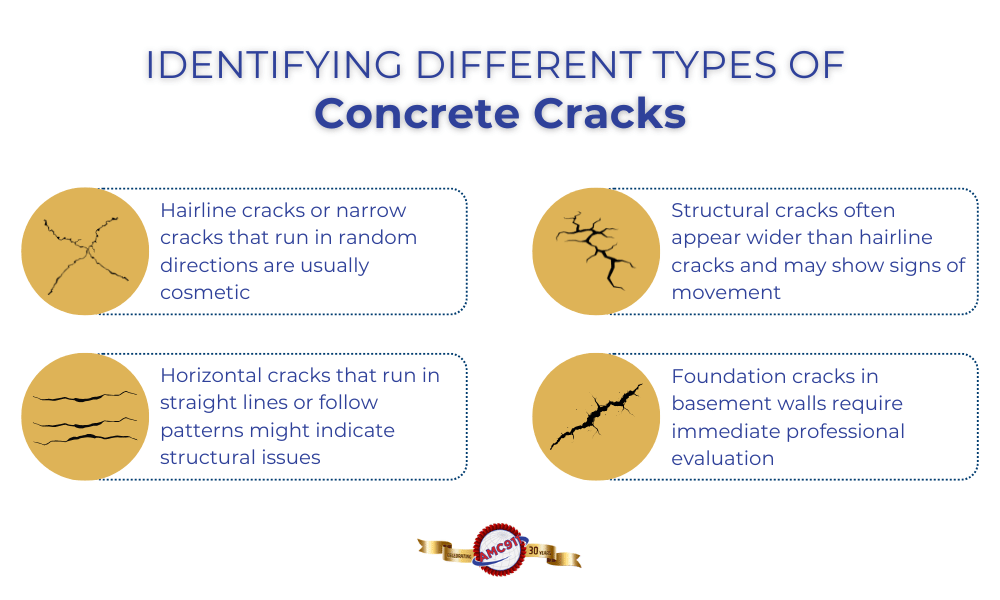

It’s important to distinguish between different types of cracks:

- Hairline cracks or narrow cracks that run in random directions are usually cosmetic

- Horizontal cracks that run in straight lines or follow patterns might indicate structural issues

- Structural cracks often appear wider than hairline cracks and may show signs of movement

- Foundation cracks in basement walls require immediate professional evaluation

Foundation cracks deserve special attention. While surface cracks in a concrete slab are typically harmless, cracks in foundation walls can signal serious structural damage. If you notice horizontal crack patterns in basement walls or foundation areas, these require immediate professional evaluation.

Control joints are designed to manage where concrete cracks occur. These intentional weak points guide crack formation to less visible areas. When cracks appear outside control joints, it often means the concrete experienced more stress than anticipated.

Essential Tools and Materials for Concrete Crack Repair

Before starting any repair, gather the right tools and materials. Having everything ready makes the process smoother and ensures better results.

Required Tools

- Wire brush to clean loose material from the crack

- Putty knife for applying filler (should be slightly wider than your crack)

- Safety glasses and work gloves for protection

- Clean cloth or vacuum for debris removal

Repair Materials to Consider

Material selection depends on your specific situation. Concrete crack filler comes in several varieties, some work better for narrow cracks while others handle wider gaps. For basic hairline crack repair, a quality crack filler that comes in a tube or cartridge offers the easiest application.

Concrete sealer is essential for finishing the job. After filling the crack, sealer protects the repair and helps it blend with the surrounding concrete surface. Choose a sealer that matches your existing concrete’s appearance.

For deeper repairs, backer rod provides crucial support. This foam material fills the bottom of wider cracks before applying filler, preventing the repair material from sinking too deep. If you’re working with larger cracks, having some concrete mix on hand allows you to build up the area before applying finish materials.

Advanced Repair Options

Epoxy injection systems offer the strongest repairs but require more skill to use properly. These work well for structural repairs or when you need a permanent solution. However, most homeowners find standard concrete crack filler adequate for typical hairline crack situations.

Crack injection equipment is typically reserved for professional use, but smaller versions are available for DIY projects. These systems force repair material deep into the crack under pressure, creating a more thorough repair than surface applications.

Step-by-Step Repair Process

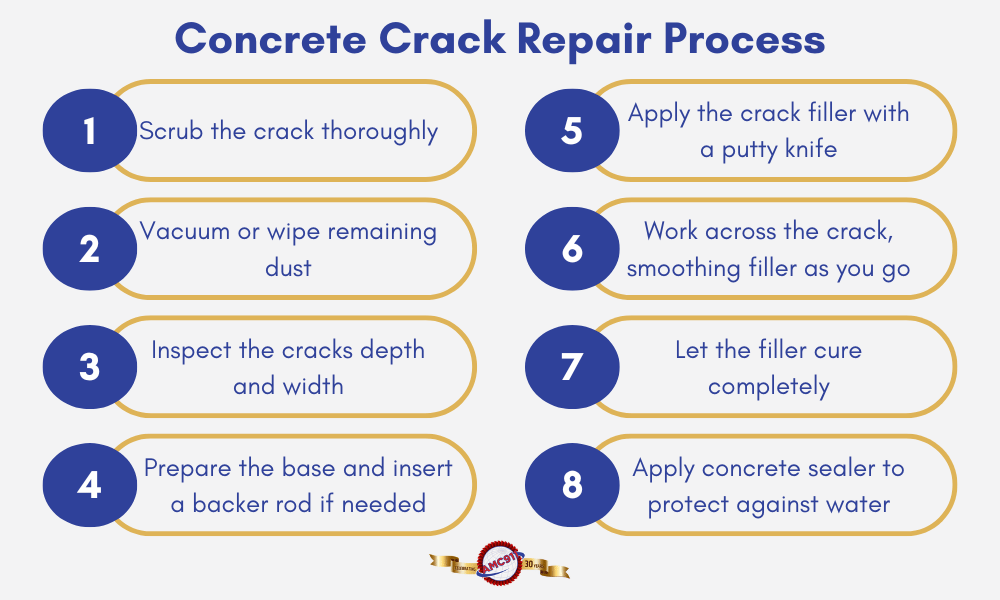

Proper preparation makes the difference between a repair that lasts years and one that fails in months. Start by cleaning the crack thoroughly with your wire brush, removing all loose material, dirt, and debris. Even tiny particles can prevent proper adhesion, so be thorough in this step.

Preparation Steps

- Clean the crack completely with your wire brush

- Remove all loose material and debris

- Vacuum or wipe away dust and particles

- Examine crack depth and width to choose appropriate materials

Filling the Crack

For narrow cracks less than 1/8 inch wide, standard concrete crack filler is effective. Apply it directly using your putty knife, working the material into the crack and slightly overfilling to account for settling.

Deep cracks require a different approach. Insert backer rod into the crack first, pushing it down about 1/4 inch below the surface. This prevents the crack filler from flowing too deep and creates a proper base for the repair. Then apply your concrete crack filler over the backer rod.

Work systematically when filling cracks. Start at one end and move steadily along the entire length. Use your putty knife to smooth the surface, removing excess material while ensuring the crack is completely filled.

Special Considerations for Different Surfaces

For concrete floors and concrete slabs, pay attention to the existing surface texture. Try to match the repair’s finish to blend naturally with the surrounding area. This is especially important for decorative concrete where appearance matters most.

Epoxy injection provides the strongest repair for significant cracks. This process involves drilling small holes along the crack, inserting injection ports, and pumping epoxy under pressure. While more complex, this method works excellently for structural repairs or when dealing with foundation cracks.

Curing and Finishing

Weather conditions affect the curing process, so plan accordingly. Avoid repairs during extreme temperatures or when rain is expected within 24 hours. Most crack fillers need several hours to cure properly before being exposed to moisture or traffic.

After the initial cure, apply concrete sealer over the entire repaired area. This protects the repair from moisture penetration and helps prevent future cracking. Allow the sealer to dry completely before normal use of the area.

When to Call Professional Contractors

While many concrete crack repairs are suitable for DIY projects, certain situations require professional expertise. Recognizing these scenarios can save you time, money, and potential safety issues.

Warning Signs That Require Professional Help

- Horizontal crack patterns that may indicate structural problems

- Water seepage through cracks

- Recurring cracks that reappear after repair

- Cracks wider than 1/4 inch

- Multiple cracks appearing simultaneously

Horizontal crack patterns often indicate structural problems that need engineered solutions. Unlike random hairline cracks, horizontal cracks may suggest foundation settlement or other serious issues. These require professional assessment to determine the underlying cause and appropriate repair strategy.

Water seepage through cracks signals more than a cosmetic problem. When cracks allow water infiltration, you’re dealing with potential structural damage and moisture issues that can affect your home’s foundation. Professional contractors have specialized equipment and materials to address these complex situations.

The AMC911 Advantage

For over 30 years, AMC911 Crawl Space & Foundation Repair has been helping Hampton Roads homeowners address complex concrete and foundation issues. As Class A contractors with an A+ Better Business Bureau rating, our team combines extensive experience with modern engineering solutions.

What sets us apart is our ability to identify the root cause of cracking problems. While DIY repairs may address surface-level symptoms, we diagnose and resolve the underlying issues that lead to cracks. Our in-house engineering team designs custom solutions tailored to your specific needs.

Our comprehensive approach goes beyond basic crack injection or surface repairs. We evaluate your entire foundation system, identify potential problem areas, and deliver solutions that help prevent future issues. This engineering-based strategy provides long-term value that quick fixes simply can’t offer.

We also stand behind our work with warranties and guarantees that protect your investment. When you choose AMC911, you’re not just getting a repair, you’re gaining peace of mind knowing the problem is truly resolved.

If you’re seeing concerning cracks, recurring damage, or signs of structural issues, contact AMC911 for a free professional evaluation. Our decades of experience with local soil conditions and climate challenges make us uniquely qualified to provide lasting solutions for your home.