A Quick Definition: Joist sistering is the process of attaching a new joist alongside an existing joist to strengthen and restore your floor’s structural integrity. This technique involves securing a sister joist parallel to the original joist using carriage bolts, construction adhesive, and proper fasteners. The process reinforces weakened floor joists without requiring complete replacement, making it a cost-effective solution for many structural problems.

Understanding when and how sistering works can help you identify potential issues early and make informed decisions about your home’s foundation health. This guide covers everything you need to know about joist sistering, from recognizing problems to understanding the repair process.

Understanding Your Floor System

Before diving into sistering techniques, it’s important to understand how your floor framing works. Your floor system consists of several connected parts that work together to support your home’s weight.

Basic Floor Components

Floor joists are horizontal wooden beams that span between support points to carry the load of your floors, furniture, and people. These structural members typically run parallel to each other at regular intervals, usually 16 or 24 inches apart according to building code requirements.

The sill plate sits on top of your foundation wall and provides the base connection point for your floor framing system. The rim joist (also called a band joist) runs perpendicular to the floor joists around the perimeter, closing off the floor system and providing additional stability.

Support Systems

Your joist system connects to several other important parts:

- Beams provide major support points where joists rest or connect

- Joist hangers secure joists to beams and rim joists

- Support columns carry load from beams down to the foundation

- Band boards enclose the floor system at the perimeter

- Deck joists extend the floor system to outdoor areas

The crawl space below your floors houses all these components and provides access for maintenance and repairs. Building codes specify minimum sizes and spacing requirements for joists based on the span distance and expected loads.

When any part of this system weakens, it affects the entire floor’s performance. The sill plate, for example, must remain level and secure to keep joists properly aligned. If support columns settle or beams sag, the connected joists will show stress.

When and Why Joists Need Sistering

Several factors can compromise your floor joist system over time. Recognizing these issues early helps prevent more serious structural problems.

Common Causes of Joist Problems

Water damage ranks as one of the most frequent causes of joist deterioration. Moisture from plumbing leaks, poor drainage, or high humidity can weaken wood fibers and create conditions for rot. An old house often shows signs of water damage in crawl spaces where moisture control wasn’t prioritized during construction.

Age and settlement naturally affect older homes. As the house settles, loads shift and put additional stress on certain joists. The original joist sizing might have been adequate when new but may no longer meet current standards or handle increased loads.

Pest damage from termites or other wood-destroying insects can hollow out significant portions of joists. Even after treating the pest problem, the damaged joist loses its load-bearing capacity.

Poor installation sometimes creates problems from day one. If joists are undersized, spaced too far apart, or improperly connected, they may begin sagging early in the home’s life.

Recognizing the Signs

A sagging floor is often the first noticeable sign of joist problems. You might feel a bouncy or spongy sensation when walking across affected areas. Furniture may wobble or shake when you walk nearby.

Visual inspection in the crawl space can reveal more specific issues:

- Sagging joists that bow downward between support points

- Cracks or splits in the wood

- Signs of insect damage or rot

- Loose connections at joist hangers or beam attachments

Sometimes a single joist shows problems while adjacent joists remain sound. Other times, multiple joists in an area need attention due to widespread water damage or settlement.

Structural failure represents the extreme end of joist problems. Before reaching this point, most issues progress through stages of increasing sag and reduced load capacity.

The Complete Joist Sistering Process

Professional joist sistering involves careful planning, proper materials, and precise installation. Understanding this process helps explain why this work requires experienced contractors.

Materials and Preparation

A structural engineer should evaluate the situation before beginning work. This assessment determines the appropriate size for the new joist and identifies any additional support needs.

Material selection depends on the existing joist dimensions and local building codes:

- Lumber for the new sister joist, typically matching or exceeding the original joist size

- Carriage bolts for the primary connection between old and new joists

- Construction adhesive to improve the bond between surfaces

- Lag screws or lag bolts for additional fastening

- Common nails for securing connections to adjacent structures

Installation Steps

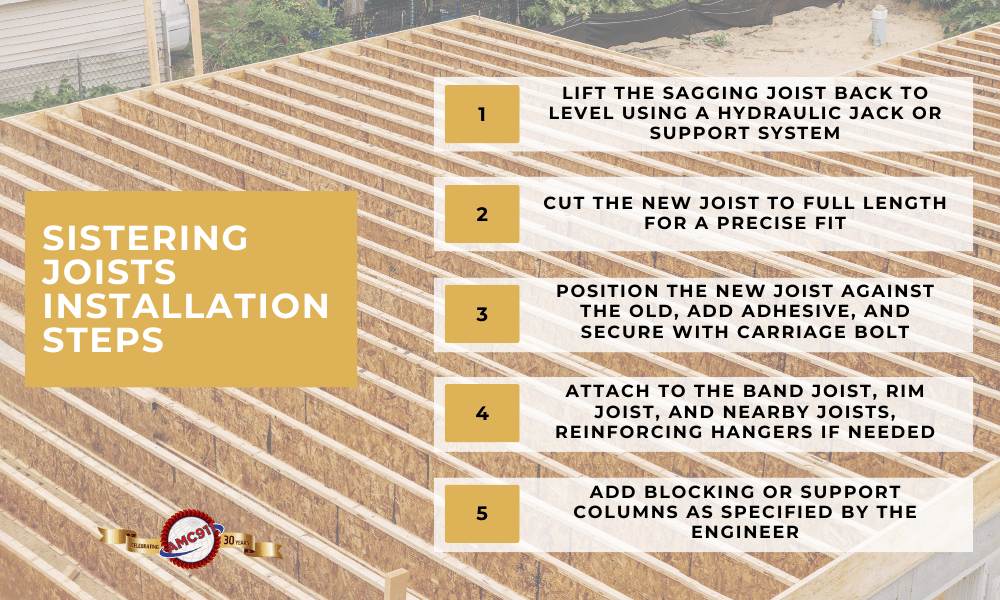

- Structural Support: Before installing a new sistered joist, contractors use a hydraulic jack or other support system to lift the sagging area back to proper level. This step relieves stress on the existing joist and ensures proper alignment.

- Measuring and Cutting: The new sister joist must be cut to full length to match the span of the original joist. Precise measurements ensure proper fit against the existing floor joist and connections to the sill plate and band board.

- Positioning and Fastening: The new sistered joist gets positioned tight against the original joist. Contractors apply construction adhesive between the surfaces before securing with carriage bolts spaced according to engineering specifications.

- Connections: Proper attachment to the band joist, rim joist, and any adjacent joist requires attention to detail. Joist hangers may need replacement or reinforcement to handle the increased load capacity.

- Additional Support: Some situations require solid blocking between joists or additional support columns underneath. The structural engineer’s plans specify these requirements.

Code Compliance and Permits

Most areas require a building permit for structural modifications like joist sistering. The work must meet current building codes, which may be more strict than when your house was originally built.

Professional contractors understand these requirements and handle the permit process. They also arrange for inspections to verify the work meets code standards.

Common Questions During Joint Sistering

How Long Does It Take To Sister a Joist?

The time required depends on joist size, condition, and project complexity. Simple projects with small joists may take a few hours, while larger or more complex jobs can take most of a day. Sistering must be done with precision to ensure proper alignment and support.

How Much Does Joist Sistering Cost?

Costs vary by lumber type, joist length, and damage severity. On average, expect $100–$300 per joist (materials only). Extensive damage or added supports can increase costs. While not cheap, sistering extends foundation life and helps prevent costly future repairs.

What About DIY Joist Sistering?

This is not a DIY project. Only licensed, experienced contractors should handle joist sistering to guarantee safety and proper structural support.

Professional Solutions and When to Call Experts

Joist sistering requires specialized knowledge and experience that goes beyond typical DIY skills. The consequences of improper installation can affect your entire home’s structural integrity.

Signs You Need Crawl Space Help

Before repairs, it’s important to recognize when your crawl space is in trouble. Call an expert if you notice:

- Sagging or uneven floors: Weak joists may be bending

- Shaking furniture: Points to failing wood supports.

Musty odors: Often caused by hidden mold.

Sticking doors or windows: A sign of shifting supports. - Cracked walls: Can stem from structural instability.

- Mold on baseboards or floors: Indicates high moisture below.

These problems only worsen over time, making professional evaluation essential.

Why Professional Expertise Matters

Structural engineers provide the technical knowledge needed to properly assess joist problems and design appropriate solutions. They understand load calculations, building codes, and how different repair methods affect the overall structure.

Professional contractors bring practical experience with installation techniques and material selection. They know how to work safely in cramped crawl spaces and handle unexpected complications that often arise during structural work.

The AMC911 Advantage

At AMC911 Crawl Space & Foundation Repair, we’ve spent over 30 years providing engineered solutions to foundation and structural problems throughout Virginia Beach, Chesapeake, Norfolk, Suffolk & Hampton Roads, Virginia. Our team understands the unique challenges that local soil conditions and climate create for home foundations.

We recognize that joist problems often indicate broader foundation or crawl space issues. Our evaluation process identifies all related problems so you can address them efficiently rather than dealing with recurring issues.

Investment in engineered solutions provides lasting value for your home. Proper joist sistering restores your floor’s load-bearing capacity and prevents progressive damage that could require more extensive repairs later.

When you choose professional installation, you gain peace of mind knowing the work meets engineering standards and will perform reliably for years to come. Our experienced team has the tools, knowledge, and commitment to quality that ensures your structural repairs provide the strong beam support your home needs.

If you’ve noticed signs of floor problems or want to have your crawl space evaluated, contact AMC911 today. We’ll provide a thorough assessment and explain your options for restoring your home’s structural integrity.