The Quick Answer: Concrete shrinkage cracks are thin, hairline cracks that naturally occur in concrete surfaces as they dry and cure. These non-structural cracks form when the concrete surface dries faster than the underlying concrete, creating tensile stress that causes the material to crack. While they may look concerning, shrinkage cracks don’t affect your concrete’s structural integrity.

The Science Behind Concrete Shrinkage

Understanding concrete shrinkage starts with knowing what happens during the curing process. This water is part of a complex chemical reaction that transforms your concrete mixture from a liquid state into the solid surface you walk on.

What Happens During the Chemical Reaction

As concrete cures, several things occur simultaneously:

- Hydration process begins – Cement particles bond with water molecules

- Moisture content decreases – Water evaporates from the surface

- Volume changes occur – The concrete contracts as it loses moisture

The challenge lies in timing. Your concrete surface is exposed to air, wind, and sunlight, causing it to dry much faster than the underlying concrete. This creates different shrinkage rates within the same slab, leading to tensile stress that eventually results in those hairline cracks.

Types of Shrinkage Cracking

- Plastic Shrinkage Cracks: These appear while your concrete is still soft, usually within the first few hours after concrete placement. Plastic shrinkage cracking happens when the concrete surface loses moisture faster than bleed water can replace it from below.

- Drying Shrinkage: This occurs over weeks and months as your concrete continues to cure and lose moisture. Unlike plastic shrinkage cracks, drying shrinkage occurs throughout the concrete as it loses internal moisture, but the amount of shrinkage may still vary depending on exposure condition

Environmental Factors That Speed Up Cracking

Your local weather plays a huge role in crack formation:

- You pour concrete during hot weather. This is because the surface dries faster during hot weather.

- You pour concrete during very windy conditions. Again, the surface of the concrete dries faster when wind blows over it.

- There’s too much water in the concrete mix. Concrete needs water, but not too much water. Since concrete shrinks when it dries out, too much water in the concrete mix means the concrete below the surface will take even longer to dry out and shrink. This creates greater tension between the concrete’s surface – which dries fast – and the concrete below the surface. Therefore, concrete shrinkage cracks are more likely to happen.

These environmental factors can turn normal shrinkage into a race between surface drying and internal curing, often resulting in more visible plastic shrinkage cracks.

Identifying Different Types of Concrete Cracks

Not all cracks are created equal. Learning to distinguish between normal shrinkage cracks and signs of serious problems can save you money and worry.

Recognizing Normal Shrinkage Patterns

What Shrinkage Cracks Look Like:

- Hairline width (you can’t fit a coin into them)

- Irregular cracks that meander across the concrete surface

- Random patterns, not straight lines

- Most common on horizontal surfaces like driveways and patios

- No vertical displacement (both sides of the crack are level)

What Shrinkage Cracks DON’T Look Like

- Vertically Displaced: If the crack is caused by concrete shrinkage, one side of the crack will not be higher than the other. Cracks that are vertically displaced are usually caused by differential settlement. See the graphic below.

- Continuous: If you see a crack without breaks, it probably wasn’t caused by concrete shrinkage. Concrete shrinkage cracks are meandering and discontinuous.

- Accompanied by corrosion: Cracks accompanied by corrosion were probably caused by rusted rebar. You won’t see any corrosion on the slab’s surface with concrete shrinkage cracks.

- Wider than hairline: If the crack is wider than hairline – that is, if you can fit a coin into it – it’s almost certainly not a concrete shrinkage crack but something more serious.

Warning Signs That Need Professional Assessment

Contact a professional if you notice:

- Cracks wider than hairline thickness

- Vertical displacement along crack lines

- Cracks that continue growing over time

- Any exposure of wire mesh or reinforcement

- Multiple cracks are forming unusual patterns

Prevention and Management Strategies

While you can’t completely eliminate concrete shrinkage, smart planning and proper techniques can minimize problematic cracking.

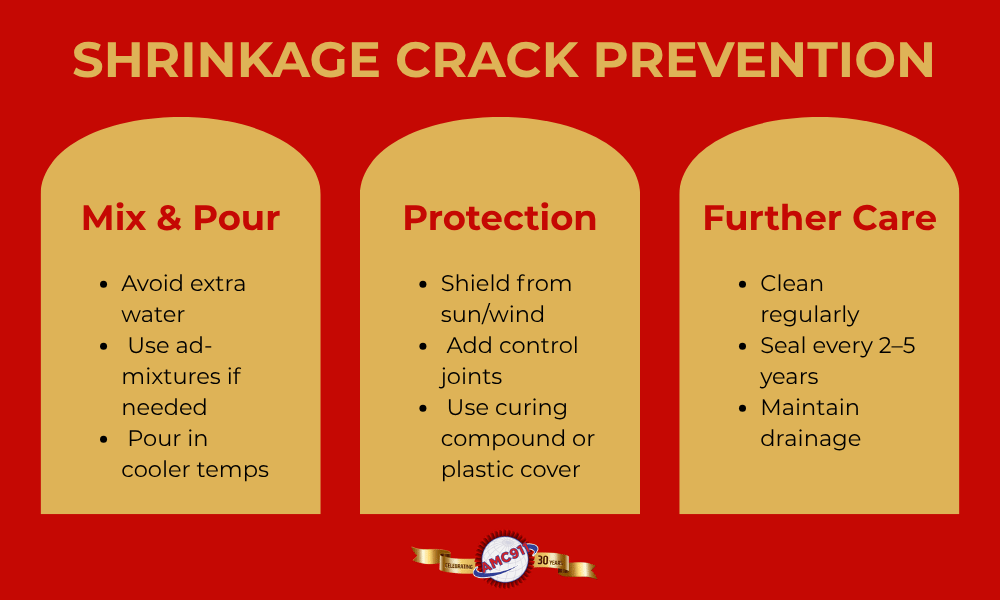

Best Practices During Construction

Concrete Mix Considerations:

- Avoid excess water in your concrete mixture

- Consider shrinkage-reducing admixtures for critical applications

- Work with your concrete contractor to select appropriate mix designs

Timing and Environmental Control:

- Schedule pours during cooler parts of the day when possible

- Protect fresh concrete from direct sunlight and wind

- Monitor concrete temperature during placement and curing

- Plan for proper curing process protection

Strategic Design Elements

Control Joints Placement: Properly spaced control joints give your concrete slab predetermined locations to crack. This helps direct any cracking to less visible areas and prevents random crack patterns.

Surface Protection Methods:

- Use temporary windbreaks during windy conditions

- Apply curing compounds to slow surface moisture loss

- Consider plastic sheeting for protection during critical curing periods

Long-Term Maintenance Tips

Once your concrete has cured, regular maintenance helps preserve its appearance:

- Clean regularly to prevent staining that makes cracks more visible

- Consider sealing exterior concrete surfaces periodically (often every 2–5 years, depending on product and exposure)

- Monitor crack development and address any changes promptly

- Maintain proper drainage around concrete slabs to prevent water-related issues

Why Choose AMC911 for Your Concrete and Foundation Needs

When concrete problems go beyond normal shrinkage cracking, you need experienced professionals who understand the complete picture. AMC911 Crawl Space & Foundation Repair brings over 30 years of specialized expertise to Hampton Roads homeowners.

Our Comprehensive Services

Foundation and Structural Solutions:

- Complete foundation crack assessment and repair

- Crawl space waterproofing and encapsulation

- Settlement and structural integrity restoration

- Drainage system installation and maintenance

Concrete Expertise:

- Professional evaluation of all crack types

- Concrete slab repair and replacement

- Preventive solutions for new construction

- Long-term maintenance planning

What Sets AMC911 Apart

Engineering-Driven Approach: Our in-house engineering team doesn’t just look at symptoms; we identify root causes. Every project gets engineered solutions designed specifically for your property’s unique conditions and soil characteristics.

Family-Owned Reliability: Founded by Brian McClung in the late 1980s, AMC911 has built its reputation on treating every customer like family. Our A+ Better Business Bureau rating reflects decades of honest, quality work throughout Hampton Roads.

Complete In-House Capabilities:

- Licensed Class A contractors

- All work performed by our own professional crews

- No subcontractors means better quality control

Local Knowledge: After three decades in Hampton Roads and the surrounding area, we understand the specific challenges your concrete faces:

- Local soil conditions and settlement patterns

- Regional weather impacts on concrete performance

- Building codes and permit requirements

- Proven solutions that work in our climate

Don’t let concrete concerns keep you awake at night. Whether you’re dealing with hairline shrinkage cracks or suspect something more serious, our experienced team can provide the answers you need. Contact AMC911 today for a thorough inspection and honest assessment of your concrete and foundation systems.

Our family has been serving Hampton Roads families for over 30 years, and we’re ready to help yours too.